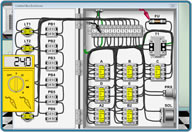

Panel Building and enclosure layout and building tips and best practiceKeep AC and DC wiring separate Always have different voltages wires cross at 90 degree angles. Never run them parallel in the same trough if possible. Keep sufficient empty space around all cabinet components to allow natural convection air flow especially when fans are not used internally within the cabinet. Do not be afraid to use a lot of circuit breakers and fuses. This will make sure the equipment is protected and make problems easier to isolate when problems occur. All ground wires should originate from a single point. Label every device possible to avoid the need to get electrical prints every time there is a problem. How many times are the prints no where to be found? Avoid running conduit into the top of any cabinet. Water, coolant, oil or moisture can seep into the cabinet and could cause damage to electrical components or cause safety hazards. Shielded cable should be used for low voltage wiring less then 5 volts or TTL should. Communications signals should utilize a shielded twisted pair cable Analog signals should be shielded. Keep electronic components heated when cold. And avoid locations next to overhead doors and areas where temperature changed drastically. Do not over tighten wire ties since they can damage and deform the internal worse. Do not bend cables tightly. Find out the minimum bend radius for cable. Preferably use at least one small fan to circulate air inside the enclosure to dissipate the heat more efficiently. Panel building design considerationsIf it is going into a dirty environment, maybe apply positive air pressure to keep out contaminants. If it is going in a dark area, mount an internal panel light. If it is an an area which it is hot, consider installing an air conditioner. If it is going in an application where liquids may possibly enter an enclosure such as wash down environments consider putting a drain hose in the bottom of the enclosure. |