|

By Warren Rhude

Equipment can malfunction for a variety of reasons. Mechanical contacts

and parts can wear out; wires can overheat and burn open or short out;

parts can be damaged by impact or abrasion; etc. Equipment may operate

in a manner far different than it was designed to, or not at all.

Typically, when equipment fails there is a sense of urgency to get it

fixed and working again. If the defective equipment is part of an assembly

line, the whole assembly line could be down causing unexpected “time

off” and lost revenue. If you are at a customer site to repair

equipment, the customer may watch you, knowing that they are paying for

every minute you spend troubleshooting and repairing their equipment.

Either one of these scenarios – and there are more, can put a lot

of pressure on you to solve the problem quickly.

So What is troubleshooting? It is the process of analyzing the behavior

or operation of a faulty circuit to determine what is wrong with the

circuit. It then involves identifying the defective component(s) and

repairing the circuit.

Depending on the type of equipment, troubleshooting can be a very challenging

task. Sometimes problems are easily diagnosed and the problem component

easily visible. Other times the symptoms as well as the faulty component

can be difficult to diagnose. A defective relay with visual signs of

burning should be easy to spot, whereas an intermittent problem caused

by a high resistance connection can be much more difficult to find.

What makes an expert Troubleshooter? One trait of expert troubleshooters

is that they are able to find virtually any fault in a reasonable amount

of time. Easy faults, complicated faults, they find them all. Another

trait is that they typically replace only the components that are defective.

They seem to have a knack for finding out exactly what is wrong. No trial

and error here. So what is their secret?

You might think that a person who has a very good understanding of how

the equipment works, should be able to troubleshoot it effectively. Being

a good at troubleshooting requires more than this.

Expert troubleshooters have a good understanding of the operation of

electrical components that are used in circuits they are familiar with,

and even ones they are not. They use a system or approach that allows

them to logically and systematically analyze a circuit and determine

exactly what is wrong. They also understand and effectively use tools

such as prints, diagrams and test instruments to identify defective components.

Finally, they have had the opportunity to develop and refine their troubleshooting

skills.

If you want to troubleshoot like the pros you will need to develop your

skills in each of these areas. Let’s look at them in more detail.

- Understand how the circuit works. This consists of understanding

the operation of all the components that are used in the circuit. This

could include such components as: push buttons, contactors, various

types of switches, relays, sensors, motors, etc.

Electrical circuits typically control or operate mechanical systems and

components. You also need to understand how these mechanical aspects

of the equipment operate to carry out the work.

You need to be able to determine how the circuit works under normal conditions

and what effect changing one of the circuit inputs has on the circuit

operation. For example, what happens to the overall circuit operation

when a push button is pressed; which relays energize, which lights illuminate,

does the pump start or stop, etc. You also need to be able to determine

what effect a faulty component may have on the circuit operation.

- Use a logical, systematic approach to analyze the circuit’s

behavior. This is critical. There are several approaches that troubleshooters

use. They may have different steps or processes but they have the

following in common: They all approach problems systematically and

logically thus

minimizing the steps and ruling out trial and error. One such approach

used to teach troubleshooting is called the “5 Step Approach”.

A summary of the key steps are:

-

Observe Most faults provide clues as to their cause. There could be visual

clues such as signs of damage or improper operation. Don’t

forget to use your other senses; sounds and smells can

also provide valuable

clues. Through careful observation and a some reasoning,

most faults can be identified to the actual component with

very

little testing.

- Define Problem Area At this stage you apply logic and reasoning to your

observations to determine the problem area of the malfunctioning

equipment.

- Identify Possible Causes Once you have the problem area(s) defined it

is necessary to identify all the possible causes of the

malfunction.

- Determine Most Probable Cause Once the list of possible causes has been

made it is necessary to prioritize the items as to the

possibility of them being the actual cause of the malfunction.

- Test and Repair Once you have determined the most probable cause, you

must test it to prove it to be the problem or not.

See A Systematic Approach to Troubleshooting for more details on this approach.

- Understand how to use tools such as prints, diagrams and

test instruments to identify defective components. Let’s first look

at prints and diagrams. Some of the key things you should be able to

determine from

these are:

- how the circuit should operate

- what kind of features the circuit has

- what voltages you should expect at various points on the circuit

- where components are physically located

- how the components are actually wired together

Various types of test instruments are available for testing electrical

circuits. The ones you choose depends

on the type of circuit and its components. A common test instrument

which is

invaluable to a troubleshooter

is a Multimeter. It is capable of measuring

voltage and resistance with

some meters capable of other measurements

such

as current and capacitance.

You must be able to determine what type of test

instrument to use, when and where to

use it, and how to safely take readings with it.

- Practice! Troubleshooting, like any skill, requires practice

to become proficient. Practice can be difficult to get.

Depending on your job,

you may not have the opportunity for enough troubleshooting practice.

And even if you do, your employer may not want you to practice troubleshooting

on equipment they depend on. Until you become reasonably competent,

it is best to practice troubleshooting in a controlled environment.

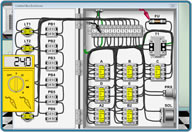

One option is to build or purchase equipment that can be used for troubleshooting.

This equipment is designed with the ability to apply faults to it. Here

you can practice your skills in a very realistic environment without

affecting equipment in use.

Another option which is gaining more popularity is the use of computer

simulations. These simulations can be extremely realistic and allow

you to practice your troubleshooting skills in a safe environment.

Some other

advantages are portability, cost effectiveness, and can be used in

almost any location. Some even include an assessment function that

assesses

the user’s troubleshooting skill, provides feedback, and records

their troubleshooting processes.

Review your own skills in each of these areas. Improving any one of

them, along with a good dose of practice, will improve your troubleshooting

skills.

About the Author:

Warren Rhude is president of Simutech Multimedia Inc. http://www.simutechmultimedia.com, an e-learning company that develops computer based training simulations for electrical troubleshooting. Warren has an electrical background and has taught troubleshooting for several years at a prominent electrical utility.

Publishers Note:

Simutech Multimedia has developed a series of award winning simulations for learning electrical troubleshooting skills. Click here for more information on these programs or to download a free demo.

|