What are the most important top troubleshooting tools and testers for the Maintenance Department and Service? |

||

When it comes to CNC and machine maintenance your main goal is to eliminate costly mistakes up front by your service department. Whether experienced or inexperienced these tools can only help your bottom line. First what are the costly mistakes?

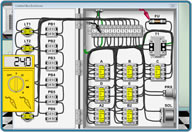

Recommended top Maintenance toolsStandard high quality meter- This is an obvious tool for your toolbox and the most important one. Buy a Quality ohm meter, typically around $300-$400. If you do not you will pay for it later and get misreading which you will not know until someone with a high quality meter checks it after you. Megohm meter for testing servo motors/motors and cables. It tests the resistance to ground and is used to determine if motor, plug, or cables are bad, coolant impregnated or beginning to fail. This is a type of meter that measures resistance in Megohms typically above 1000 megohms or 1,000,000,000 ohms. The average ohm meter can have a maximum range of anywhere from 1meg to 30megohms. Phase Rotation meter- This meter is handy when a company moves machines around or adds machines to facility. I can not tell you how many service calls are generated because a company hooks the phasing up wrong. Many of you think I just watch for rotation. Hydraulic pump, etc. Sometimes that may work sometimes it does not. Just because the drives come up and the axis moves the right direction does not mean that it’s phased right! Coolant pumps, hydraulic pumps, cooler pumps can all be damaged when phase is wrong and more. Fused Jumper for testing machine Inputs and output devices- This is a must have and has saved my reputation as a service engineer many times over. This is simply a 1amp fuse inline with two meter probes and a bunch of different attachments. Drawbar clamp force dynamometer clamprite Quality soldering iron

CNC Specialty Store |

||

Buy All of the Maintenance tools above from our